HOME

K-TRAP

What is STEAM TRAP?

K-TRAP

What is STEAM TRAP?

What is STEAM TRAP?

The factory uses STEAM for heat insulation, heating, heat exchange, etc., and the SETAM is transferred to the required place through piping.

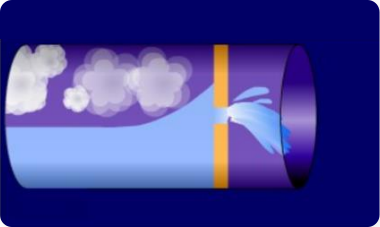

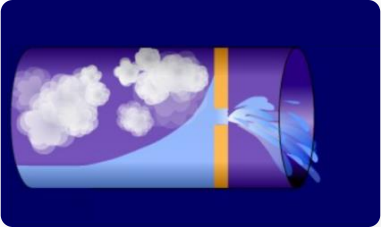

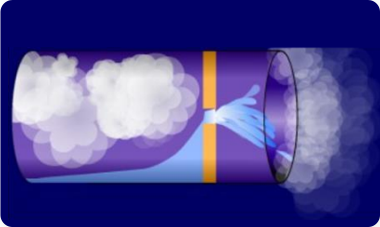

The STEAM creates condensate in the pipe due to the temperature difference with the outside and the heat exchange on PROCESS.

The condensate creates a bottleneck and promotes corrosion in the pipe.

The STEAM TRAP discharges only the condensate in the pipe and the STEAM holds it to solve the above problem.

Thermodynamic type steam trap

(Thermodynamic Steam Trap, Disk Type Steam Trap)

- The initial operating self-condensing water is discharged through the orifice under the introduced pressure

- When condensate is introduced, the pressure at the bottom of the disc drops and re-evaporates

- The pressure difference between the top and bottom of the disc causes the disc to go down and at the same time re-evaporate vapor flows into the top of the disc and closes the valve

- When the re-evaporated vapor in the chamber on the top of the disc is condensed by heat dissipation, etc., the disc rises again and opens to discharge the condensed water

Advantages of Thermodynamic Steam Traps

- Available for high pressure and superheated steam

- The condensate treatment capacity is larger than the caliber

- be resistant to water hammer

Disadvantages of Thermodynamic Steam Traps

- Noise is high during operation and vibration may be caused by back pressure

- Must be used below maximum allowable back pressure (approximately 80% of inlet pressure) Life may be shortened due to increased number of operations during oversizing

- Air binding is that it is.

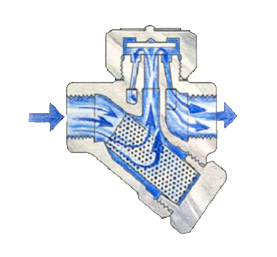

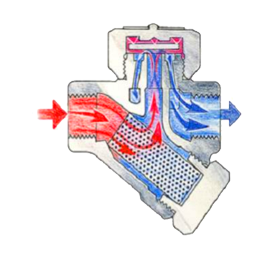

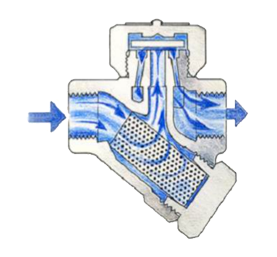

Pressure balanced steam trap

(Thermostatic Steam Trap, Diaphragm Type Steam Trap)

The pressure balanced steam trap, also known as diaphragm steam trap, uses the temperature difference between steam and condensate to allow sealed capsules with boiling points lower than the boiling point of water to evaporate and close the valve when condensed.

Advantages of Pressure Equilibrium Steam Traps

- Available for high pressure and superheated steam

- The condensate treatment capacity is larger than the caliber

- Strong in the water hammer.

Disadvantages of Pressure Equilibrium Steam Traps

- Noise is high during operation and vibration may be caused by back pressure

- Must be used below maximum allowable back pressure (approximately 80% of inlet pressure) Life may be shortened due to increased number of operations during oversizing

- Air Binding is present

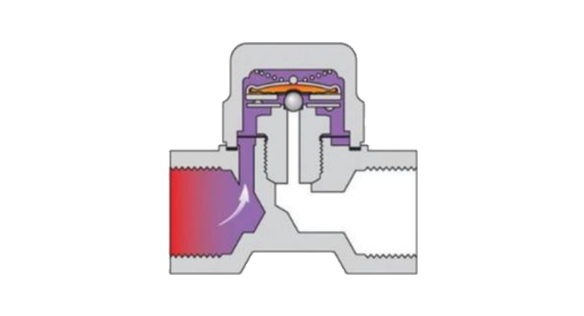

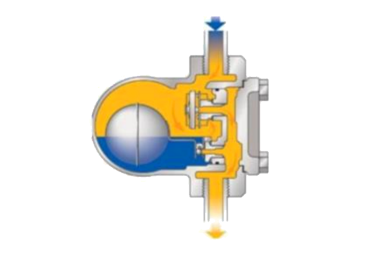

Mechanical type steam trap

(Mechanical Steam Trap, Ball Float Steam Trap)

Advantages of Mechanical Steam Traps

- Condensate continuous discharge of condensate prevents condensate stagnation on the heat transfer surface and is suitable for application of process facilities

- Condensate discharge capacity is large

- Not influenced by the rapid change of pressure and flow.

Disadvantages of Mechanical Steam Traps

- Condensate inside the trap all the freeze because of the greater concerns

- The volume of the trap is relatively large and the heat dissipation loss is large

- Vulnerability to the corrosive fluid

Orifice type steam trap.

(Orifice Type Steam Trap)

It is a structure in which condensed water is discharged through a fixed orifice hole by using the difference between the steam moving speed (about 30 times the condensate moving speed) and the condensate moving speed.

Advantages of Orifice Steam Trap

- Low maintenance due to no movement structure

- Easy installation with a simple structure.

Disadvantages of Orifice Steam Trap

- Condensate at variance in response difficult.

- Blockage or enlargement of the orifice hole may cause problems and steam loss in condensate discharge.