HOME

Technical data

Steam Leakage Test

K-TRAP

Steam Leakage Test

Steam Leakage Test

Steam leakage test of steam trap is carried out using test equipment based on ISO 7841.

-

Steam Leakage Test

-

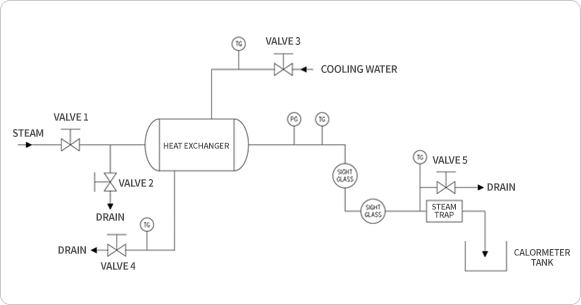

Test Facility System Diagram (P&ID)

01. With the test pressure not exceeding 3.2 MPa in the saturated vapor state (238℃), the test may be performed at a pressure corresponding to the highest operating pressure of the trap.

02. Start the test with all valves closed and the tank empty.

03. Open the water drain valve with ease of 1, 5 and, to examine the operating devices at test pressures.

04. Measure and record the weight of the empty calorimeter tank during commissioning, and record the vapor pressure and steam temperature.

05. Fill the calorimeter tank with sufficient water to test run during the actual period. Record the initial water temperature and mass combined with the tank.

06. When the test equipment reaches thermal equilibrium, close valve 5 and open valves 3 and 4.

07. After conducting the test for a certain period of time, record the sum of the final temperature of water in the calorimeter and the amount of water and tank well.

08. In order to minimize errors and improve the accuracy of the test, conduct three consecutive tests, and allow the deviation of the values obtained from each test to be within 10% or 500 g/h.