HOME

Technical data

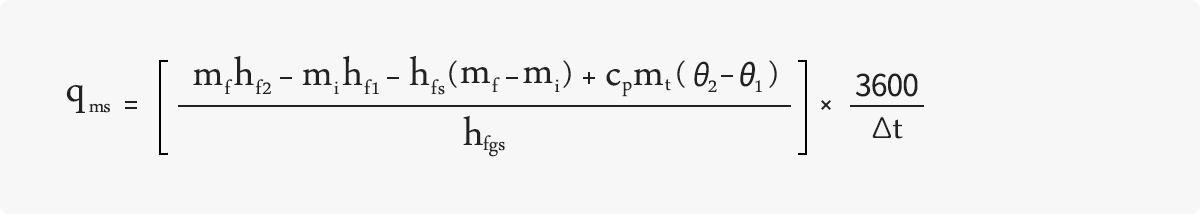

Vapor Leakage Calculation Formula

K-TRAP

Vapor Leakage Calculation Formula

Vapor Leakage Calculation Formula

Quantitative assessment of steam loss and energy savings that can be achieved by trap switching.

Steam condensate water capture steam condensate losses arising from facilities in the test of certainty by referring to the energy analysis can be identified.

Condensate collection test is effective to verify cost-effectiveness prior to facility improvement work.

According to the steam condensate collection test, the amount of steam leakage is measured quantitatively.

Put about 10 to 20L of water in a container and measure the water volume and water temperature.

The drain from the outlet of the steam trap, and two fluids of leaked steam, are guided into the water to absorb all of the water for one to three minutes.

Measure the water volume and the temperature of the water after completion of the operation. By entering these data into a given equation, the amount of steam leakage can be quantified.

-

Loss of steam.

-

A calorimeter mass at the beginning of the water

-

Final mass of the condensate and water calorimeter.

-

In the first moment, the calorimeter and the mass of water

-

At the final moment, the calorimeter and the mass of water

-

Calorimeter mass of the tank

-

Vitality of the initial water in the calorimeter

-

Bi-deposition of final condensate and water in the calorimeter

-

Biitalization of liquid in the vapor inlet state

-

Steam inlet condition of specific enthalpy.

-

Specific heat of calorimeter material

-

Calorimeter tank at the beginning of the water temperature.

-

Calorimeter tank of water temperature.

-

A time interval