HOME

Business

PIPING SPOOL

Business

PIPING SPOOL

Piping Spool Fabrication by Computerized Automatic Welding.

-

Position

1G

-

Speed

2~12mm/sec

-

Information

1st Layer by GTAW / 2nd and over Layer by FCAW

-

Range of diamete

2~52"

-

Range of thickness

Max. 70mm

-

Material

Carbon Steel / Stainless Steel / Low-Alloy SteelNickel Alloy / Titanium and etc.

Productivity Analysis

Productivity of Automatic Welding System is about three (3) times higher than manual welding

| Size | SettingTime | Automatic Welding | Manual Welding | ||||||

| Welding Time | Finish Time | Total Required Time | Daily AVG. Welding | Welding Time | Finish Time | Total Required Time | Daily AVG. Welding | ||

| 2"~3" | 2M 30S | 5M | 2M | 9M 30S | 130" | 20M | 3M | 23M | 42" |

| 4"~8" | 3M | 7M | 2M | 12M | 200" | 35M | 4M | 39M | 50" |

| 10"~14" | 4M | 13M | 2M | 19M | 200" | 60M | 6M | 66M | 50" |

| 16"~20" | 7M | 30M | 3M | 40M | 190" | 3H 30M | 10M | 3H 40M | 44" |

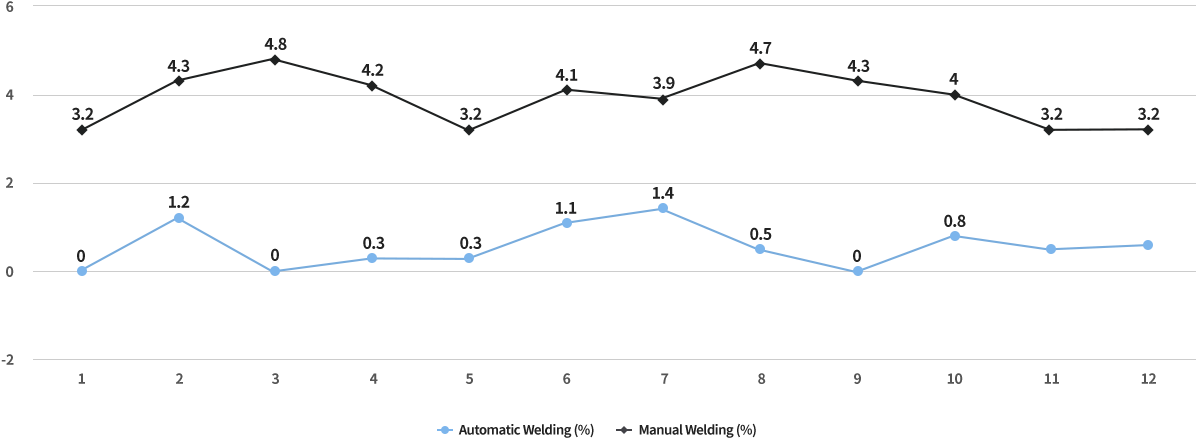

Quality Analysis

(Radiographic Test Result Trend for 3 Months)

| Section | M1 | M2 | M3 | Total | |||||||||

| M1 | M2 | M3 | M4 | M1 | M2 | M3 | M4 | M1 | M2 | M3 | M4 | ||

| Reject Rate | 0% | 1.2% | 0% | 0.3% | 0.3% | 1.1% | 1.4% | 0.5% | 0% | 0.8% | 0.5% | 0.6% | 0.53% |

| Reject Sheets | 0 | 0 | 0 | 2 | 2 | 4 | 6 | 2 | 2 | 2 | 1 | 3 | 24 |

| Shooting Sheets | 6 | 168 | 609 | 764 | 612 | 376 | 425 | 366 | 235 | 234 | 207 | 445 | 4457 |

Reject Rate

Welding Process

| Section | Welding Process | Welding Position | Welding Rod | Range | |

| Automatic Welding | Root Pass | GMAW Mixed Gas(Ar+CO2) / Metal Active Gas |

1G | Roll - Solid Wire ER70S-6 (Spoolarc86) - Φ0.9, Φ1.2 |

2" ~ 52" |

| Second and Over Layer | FCAW Mixed Gas(Ar+CO2) / Flux / Metal Active Gas |

1G | Flux Cored Wire E71T-9M (D.S7100SM) - Φ1.2, Φ1.6 |

2" ~ 52" | |

| Manual Welding | Normal Work for Piping Spool Fabrication |

GMAW | All Position | Solid TIG Wire * ER70S-6 - Φ2.4, Φ3.2 |

BOSS and under 2" |

| GMAW | All Position | E7016 - Φ 2.6, Φ3.2, Φ4.0 | No Limit | ||

| SMAW | All Position | - | Structure and Etc. | ||